Triton 2015-2018 UPPER CONTROL ARMS

KWD 219.000

- Designed to optimise wheel alignment and increase clearance with raised height suspension.

- Quantity Required : 1

- Package Details : Pair

Description

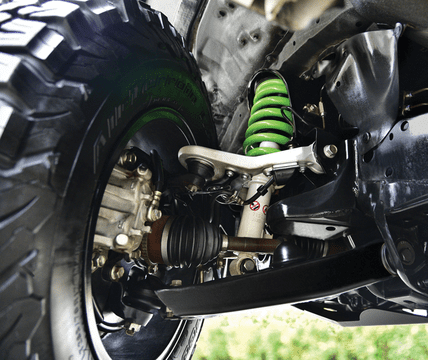

The Ironman 4×4 upper control arms (UCAs) are engineered for the Mitsubishi Triton 2015-2018

as stronger, smarter solution to the OEM UCAs.

Ironman 4×4 upper control arms are forged with 4 degrees of caster correction for ideal wheel alignment, correcting the vehicle’s geometry back to OEM specs, generating outstanding performance and ride quality.

The Pro Forge UCAs feature drop forged construction resulting in improved strength to weight ratios, increased directional strength with reduced stress concentrations in corners and filets. The precision of drop forging consistently results in superior in strength, weight savings, and manufacturing tolerances when compared to machined, rolled, or other cast processes.

Wrapped in a hardened zinc coating, these UCA’s have up to 75% more corrosion resistance when compared to traditional paint or powder coating. This zinc coating provides maximum effectiveness at warding off the oxidation that typically leads to rust and corrosion.

We use OEM style ball joints and bushings that are tested and manufactured to strict Japanese specifications that are readily available at every dealership and parts store. They feature a fully hardened stud bound in a watertight sealed machined housing which doesn’t allow for contaminates to be introduced into the joint with grease guns or outside environment.

These feature packed control arms when paired with our suspension kits translate into unmatched off-road performance, and on-road ride quality for your rig.

FEATURES

- Pro Forge Technology – Improved strength to weight ratio, with Increased directional strength reduced stress concentrations in corners and filets Increased strength and weight savings compared to machined, rolled, or cast parts

- Optimize Wheel Alignment at Raised Ride Height

- More Clearance for Larger Tires and Increased Lift

- Drop forged construction – 6082 T6 Drop Forged Alloy Construction. Zero tolerance manufacturing process compared to rolled steel and tubular constructions

- Hardened zinc coating – 75% more corrosion resistance over tradition paint or powder coating

- Built in 4 degrees of caster – for optimal wheel alignment at zero and full tuck, resetting the vehicle’s geometry to OEM specs.

- High Strength and Durability

- Sealed ball joint – doesn’t allow for contaminates to be introduced to the joint through a dirty grease gun.

- OEM spec ball joints and bushings – tested and manufactured to strict Japanese specifications, with parts available at every dealership and parts store

- Manufactured in and conforms to Australian Design Rules (ADR)

- Kit is sold as a pair

Additional information

| Brand |

|---|

- Mitsubishi, TRITON MQ L200, 2018

- Mitsubishi, TRITON MQ L200, 2017

- Mitsubishi, TRITON MQ L200, 2016

- Mitsubishi, TRITON MQ L200, 2015

Related Products

JEEP XJ Rubicon Express 3.5 Inch Super-Ride Short Arm Lift Kit with Rear Add-A-Leafs – No Shocks

LC200 REAR HEAVY COIL SPRINGS

LC200 FRONT NITRO GAS SHOCK

LC100 FRONT TORSION BARS

High Pressure Sleeve Kit CB6003

PATROL Y62 2010+ REAR FOAM CELL SHOCK

LC200 FRONT MEDIUM COIL SPRINGS

LC200 FRONT LIGHT COIL SPRINGS

LC200 REAR STANDARD COIL SPRINGS

RENAULT DUSTER REAR Medium COIL SPRINGS

LC100 FRONT DIFF DROP

PATROL Y60 REAR Full Air Suspension Kit

LC200 FRONT HEAVY COIL SPRINGS

JEEP WRANGLER JK 2 dr Rubicon Express 2.5 Inch Standard Coil Lift Kit with Twin Tube Shocks

LC100 HARD REAR FOAM CELL PRO SHOCK

LC200 HARD REAR FOAM CELL PRO SHOCK

LC200 FRONT FOAM CELL SHOCK

LC100 FRONT FOAM CELL SHOCK

JEEP WRANGLER JK 4 dr Rubicon Express 2.5 Inch Standard Coil Lift Kit with Twin Tube Shocks

LC100 FRONT TORSION BARS

Duster 2010+ CAMBER BOLT KIT

LC200 REAR EXTRA HEAVY COIL SPRINGS

LC100 / LX470 REINFORCEMENT BRACKETS

LC100 FRONT FOAM CELL PRO SHOCK

LC100 HARD REAR FOAM CELL SHOCK

Rubicon Express Shock Clamp

LC200 FRONT FOAM CELL PRO SHOCK

PATROL Y62 2010+ FRONT SWAY BAR

LC200 STRUT MOUNT

JEEP XJ Rubicon Express 3.5″ Super-Ride Short Arm Lift Kit with Rear Add-A-Leafs and Twin Tube Shocks

LC200 FRONT SWAY BAR

LC100 REAR EXTRA HEAVY COIL SPRINGS

PATROL Y62 2010+ REAR NITRO GAS SHOCK

PATROL Y62 2010+ REAR SWAY BAR